Diagnosing apparent step loss on the laser cutter

in Making on April 2, 2019 | Laser Cutting

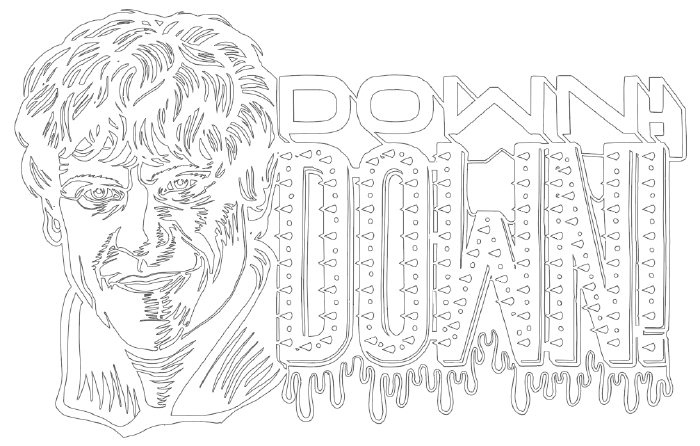

Recently I was asked by Julia Williams to help out with her Game of Thrones art project. She has some rather complicated hand drawn stencils she wanted me to cut out of A4 cardstock.

The issue

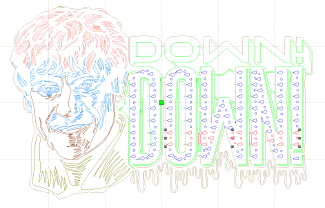

As you can see, my first run had some pretty obvious errors. My first impression was that I was losing steps so I tried to remove all the extra appliances from the circuit to see if that increased accuracy. Also, due to the way my laser operates, I can issue a pulse at origin, start the program and then when it is finished it will attempt to return to the origin where I can pulse again and see the error much easier

At this point I was starting to lose confidence that my issue was actually step-loss or signal noise. The main reason I was doubting this was that the error was very replicatable. Every time I would run the program and I measured the error it had very little deviation.

What is backlash

Backlash is the space between the teeth of engaged gears. Every geared system has some amount of backlash and since my laser does not have encoders like some of the more expensive machines so there is no feedback after a move command. Because of this, each time either axis motor reverses direction there is a small amount of backlash error that gets added to the position of the laser head. With a complicated enough path, over time the error will accumulate and every relative move will slowly drift off position.

A solution

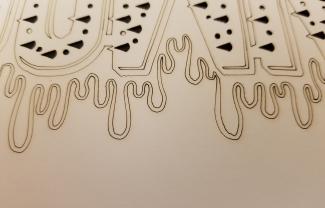

My laser has the ability to rehome and then return to the relative origin. This can be used to clear backlash error inbetween program runs. I grouped up paths into about 8 separate runs and the results were pretty great.

Comments (1)

Neil Rosenberg

Wednesday, Jan 1, 2020

Thank you

Your comment has been submitted and will be published once it has been approved.

OOPS!

Your comment has not been submitted. Please go back and try again. Thank You!

If this error persists, please open an issue by clicking here.

Say something