Herringbone Gears for Stepper Motor

in Modeling on August 26, 2018 | OpenScad 3D Printing Desk Lift

I want to try to automate my standing desk so that getting it into the exact position when standing is easier.

The NEMA17 steppers I have lying around are a bit hard to identify but I think they’re going to give me ~3.5 ft/lb.

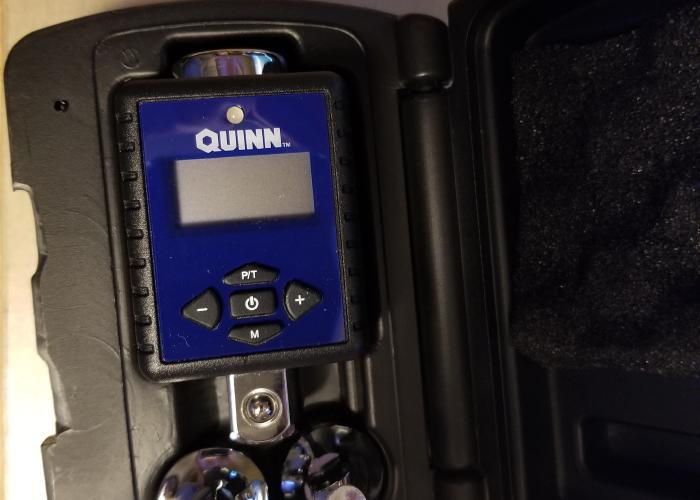

My desk is a MultiTable. I bought a digital torque wrench from Harbor Freight but it is not sensitive enough to give me the amount of force required to raise the desk. I do know that it must be somewhere under 20 ft/lb. I’ll just print out some prototypes and see if I can’t figure anything else out.

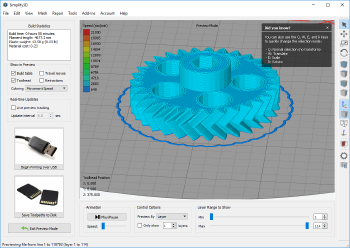

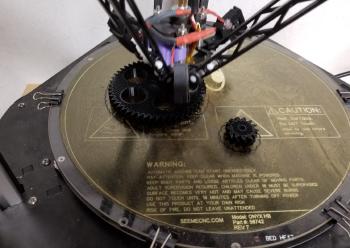

I’m using the parametric herringbone script for now. Here’s the settings from my first attempt:

// OPTIONS COMMON TO BOTH GEARS:

distance_between_axels = 35;

gear_h = 10;

gear_shaft_h = 7 ;

// GEAR1 (SMALLER GEAR, STEPPER GEAR) OPTIONS:

// It's helpful to choose prime numbers for the gear teeth.

gear1_teeth = 13;

gear1_shaft_d = 5.25; // diameter of motor shaft

gear1_shaft_r = gear1_shaft_d/2;

// gear1 shaft assumed to fill entire gear.

// gear1 attaches by means of a captive nut and bolt (or actual setscrew)

gear1_setscrew_offset = 3.5; // Distance from motor on motor shaft.

gear1_setscrew_d = 3.5;

gear1_setscrew_r = gear1_setscrew_d/2;

gear1_captive_nut_d = 6.2;

gear1_captive_nut_r = gear1_captive_nut_d/2;

gear1_captive_nut_h = 3;

// GEAR2 (LARGER GEAR, DRIVE SHAFT GEAR) OPTIONS:

gear2_teeth = 31;

gear2_shaft_d = 0;

gear2_shaft_r = gear2_shaft_d/2;

// gear2 has settable outer shaft diameter.

gear2_shaft_outer_d = 18;

gear2_shaft_outer_r = gear2_shaft_outer_d/2;

// gear2 has a hex bolt set in it, is either a hobbed bolt or has the nifty hobbed gear from MBI on it.

gear2_bolt_hex_d = 9;

gear2_bolt_hex_r = gear2_bolt_hex_d/2;

// gear2_bolt_sink: How far down the gear shaft the bolt head sits; measured as distance from drive end of gear.

gear2_bolt_sink = 0;

// gear2's shaft is a bridge above the hex bolt shaft; this creates 1/3bridge_helper_h sized steps at top of shaft to help bridging. (so bridge_helper_h/3 should be > layer height to have any effect)

bridge_helper_h=-1;

gear2_rim_margin = 2;

gear2_cut_circles = 5;

This should give me a ratio of about 2.38.

Thank you

Your comment has been submitted and will be published once it has been approved.

OOPS!

Your comment has not been submitted. Please go back and try again. Thank You!

If this error persists, please open an issue by clicking here.

Say something